When the existing flat roof above the International Departure Lounge at Gatwick Airport’s North Terminal was failing, Kemper System’s liquid applied waterproofing was the first port of call.

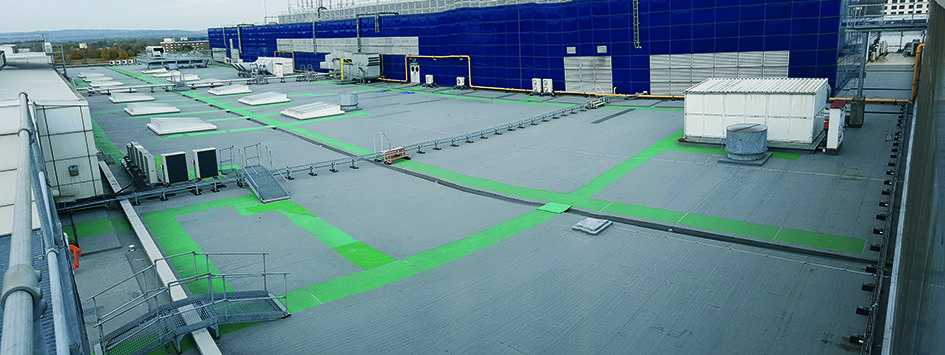

Working closely with contractors, Mitie Tilley Roofing, Kemper System’s Stratex Warm Roof system was specified using its solvent-free Kemperol 2K-PUR liquid waterproofing as part of a full refurbishment of the 2,500 sq. m roof area.

Severe water ingress into the retail and restaurant units below meant the project was time critical to prevent any further issues as well as potential profit loss for retailers. Chosen for its odourless, quick application and versatile qualities, the fleece-reinforced, liquid waterproofing system by Kemper System meant contractors could adhere to the strict timescales and operational restrictions.

Mitie Tilley Roofing first removed 250 tonnes of the existing roof ballast. The substrate was cleaned prior to applying Kempershield Type 1 Primer and Kempershield Vapour Barrier. A combination of 123mm Kempertherm FR and Kempertherm TR Tapered PIR Insulation Board was installed onto the main roof area, including the guttering.

The Kemperol 2K-PUR resin was then applied in a single, wet-on-wet process. The roof area presented numerous complexities and detailing, including five, large air-handling units, adjacent glazed facades and 36 separate large plinths with their own steel work, cable trays and pipe supports.

The versatility of the Kemperol system and ease of application meant contractors could provide a watertight, seamless membrane that incorporated all of the flat areas, complex details and outlets on the roof structure.

Much of the refurbishment works were completed overnight within a four-hour working window as the client requested no disruption to the retailers in the terminal below.

Warren Stuart, aviation director at Mitie Tilley Roofing, said: “This was a challenging refurbishment as the client demanded the highest of QHSE (Quality, Health, Safety & Environment) standards within tight timescales. The project required a leak free installation, guaranteed for 25 years with zero defects and absolutely no standing water on the roof.

“Installation also had to be flame free, environmentally friendly and odour free due to the five air-handling outlets on the roof. The timescales involved on this project were also extremely challenging, allowing less than six months.

“Kemper System ticked all the boxes. Having installed Kemperol before, we knew it was quick and easy to apply as well as versatile and durable. Its wet-on-wet application meant possession times on-site were also decreased.

“Thanks to the speed of installation and efficient programme of works, the airport’s retail units did not experience any ‘down time’ due to the refurbishment.”

Stuart Hicks at Kemper System Ltd, added: “Kemperol 2K-PUR was specified for this refurbishment because of its speed of application, solvent-free and odourless qualities. A further benefit is that 80% of the applied polyols (resins) are obtained from renewable sources, adding to the green credentials of the project.”

In 2017, the refurbishment was recognised at the NFRC (National Federation of Roofing Contractors) UK Roofing Awards with Mitie Tilley Roofing and Kemper System winning an award in the Liquid Applied Roofing and Waterproofing category.

www.kemper-system.com/UK/eng/home/